NATIONWIDE INFRARED SERVICES

Inspection solutions for every industry

Your Complete Source For Preventive Maintenance, Risk Management, And Sustainable Energy Programs

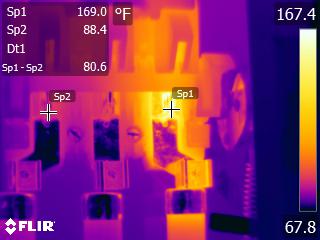

Electrical Infrared Inspections

Our Certified Thermographers Quickly and Non-Destructively Pinpoint Visually Undetectable Electrical and Mechanical Problems.

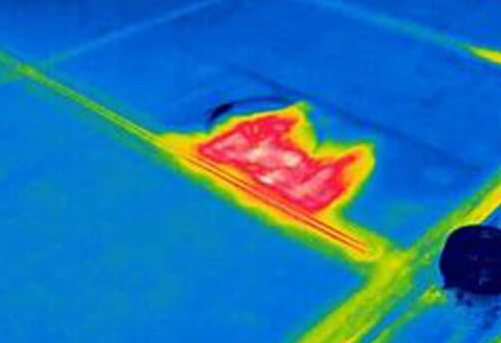

Roof Moisture Detection

Energy Sustainability Programs

Energy Saving Programs Tailored to your Needs to Increase your Revenues, Decrease your Expenses, and Most Importantly Help our Planet.

Mechanical infrared scanning

Mechanical Testing Detects Heat from Wear and Friction at its Earliest Stages and Allows for Preemptive Corrective Action.

Gas Leak Detection

Identify and Quantify Gas Leaks and Fugitive Emissions with Global Infrared’s Gas Detection and Monitoring Solutions.

Additional Services

Building Moisture Scan, Outlet Testing, GFI, Safety & Risk Maintenance Training, Vibration Generator, & More

MAJOR SCOPE OF INFRARED INSPECTIONS:

ELECTRICAL

- All Switchgear

- Utility substations, transformers and feed poles

- Main incoming services, plant main knives

- Capacitor banks

- Main switchboards and disconnects

- Main distribution panels and main disconnects

- Uninterruptible power supplies

- Generator controls, connectors and transfer Switches

- Lighting and receptacle panels

- Disconnects and combination starters

- Service disconnects for motors

- Machine control panels

- Chillers

- Motors

- MCC’s

- Air Handlers

- High Voltage Equipment

- ATS

- VFD’s

- NEC/OSHA, etc

MECHANICAL

- Boilers

- Furnace Tubes

- Refractory lined Vessels

- Pumps

- Motor Bearings

- Pad Mounted Transformer Cooling Fins

- Conveyor Bearings

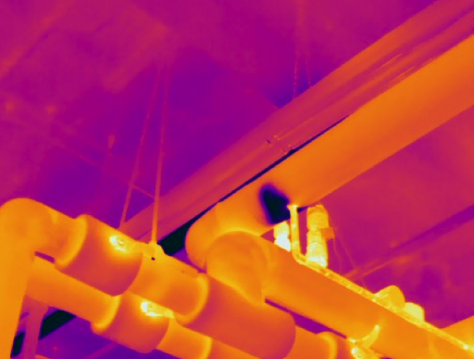

Example of Mechanical Inspection which include refractory failure inspections. This is an 8 foot manway where the refractory has fallen / broken away. High heat temperatures will cause metal fatigue and can cause a BLOW OUT in that area.

POWER PLANTS & UTILITY SERVICES

- Transmission and Distribution Lines (Ground and Aerial)

- Utility substations, transformers and feed poles

- Capacitor banks

- Underground Vaults

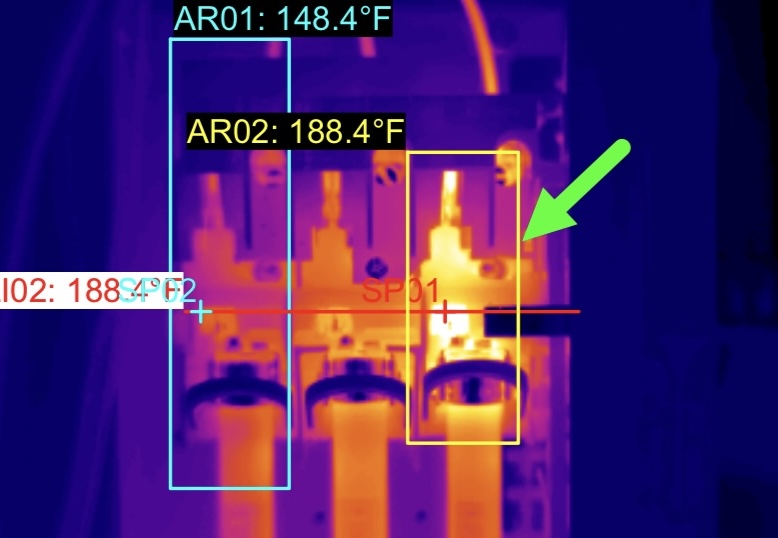

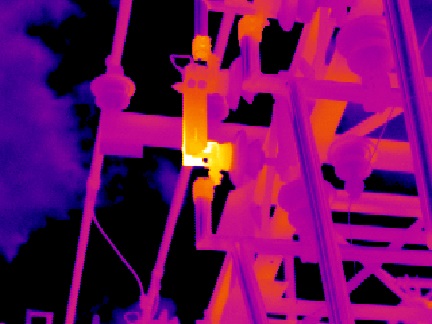

This is a Knife Switch in an electrical substation for a power company. The LOAD side of the switch is hot due to a lose or corroded connection/contact area.

Testing That Has The Highest Return On Investment

They Say a Picture is Worth A Thousand Words... But These Pictures Will Save You Thousands of Dollars.

“When an Infrared Inspection Program is Coupled with Timely Maintenance Repairs and Equipment Condition Improvement, it is Common for the Return on Investment to be on the Order of Ten Times the Cost of the Program.”