Thermal Scan Energy Inspections and Audits

SUSTAINABLE ENERGY With Global Infrared

Partnering with Global Infrared can help your company with energy saving programs tailored to your needs to increase your revenues, decrease your expenses, and most importantly help our planet.

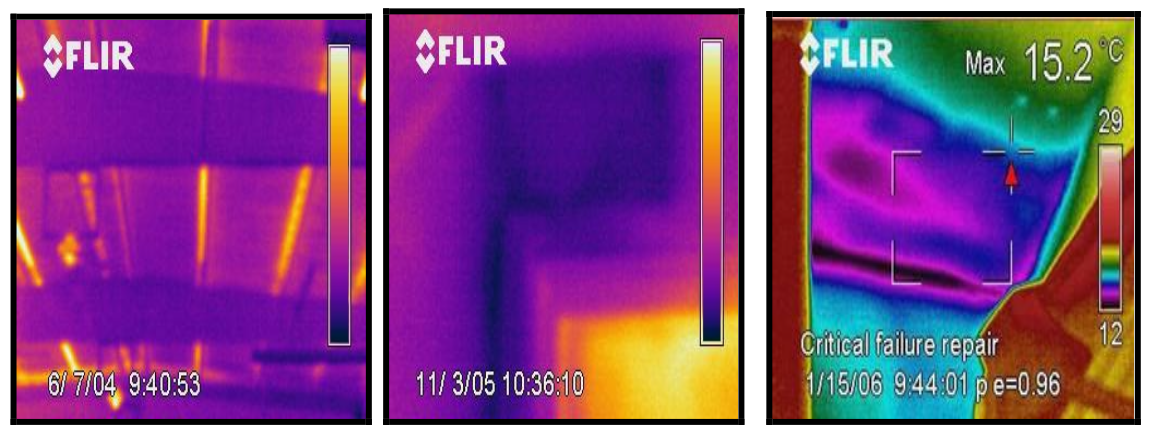

Envelope & Roof:

Infrared Scanning

When Poor Installation Occurs..

Energy Is Lost.

Energy loss from both heating and cooling is the one of the most preventable aspects of lost income. Making Infrared Thermal Scanning of your building envelope a regular part of your overall Predictive Maintenance Program will save you 10’s of Thousands of Dollars every year.

The potential energy savings from reducing drafts may range from 5% to 30% per year.

We check for indoor air leaks, such as gaps along the baseboard or edge of the flooring and at junctures of the walls and ceiling.

Check to see if air can flow through these places:

- Electrical Outlets

- Switch Plates

- Window Frame

- Baseboard

- Weather Stripping Around Doors and Walls.

We look for gaps around pipes and wires, electrical outlets, foundation seals, etc. We check to see if the caulking and weather stripping are applied properly, leaving no gaps or cracks, and are in good condition. Inspect windows and doors for air leaks.

Second and most important we use Thermography to record the temperature variations of the building’s skin, ranging from warm regions to cooler areas. The resulting images help the auditor determine whether insulation is needed. They also serve as a quality control tool, to ensure that insulation has been installed correctly. We detect poor insulation, heat loss, moisture, infestations, molding, and leaks.

ENERGY SUSTAINABLE!

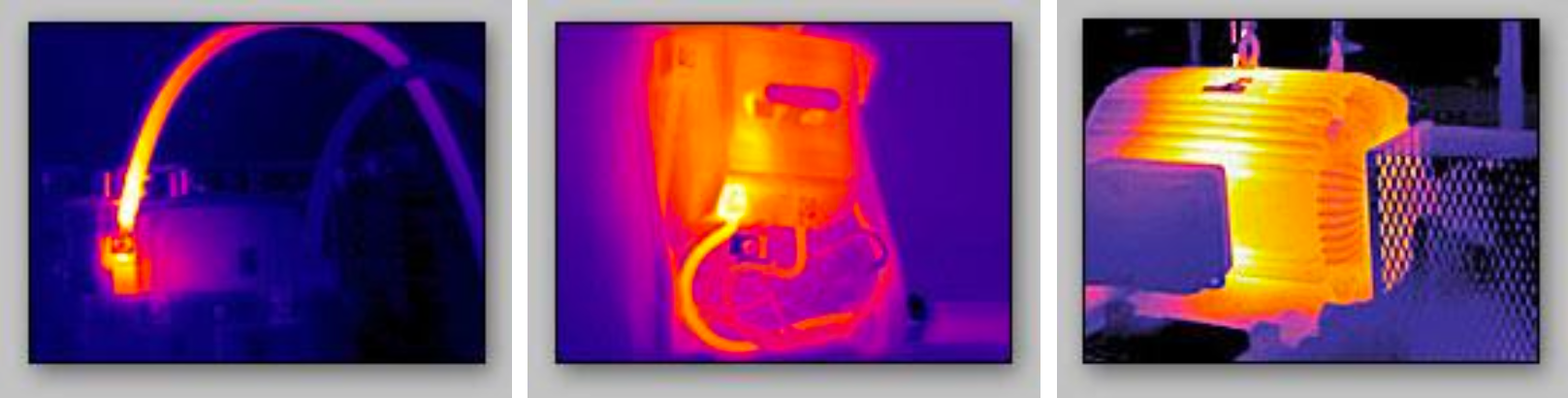

Electrical & Mechanical:

Infrared Scanning

When Equipment Runs Hot...

Energy Is Lost.

Take a piece of equipment that typically runs at 100 degrees, it seems to be running just fine and visually looks fine. That is the case with the images above. Infrared sees what the naked eye cannot see. When equipment is running 20-100+ degrees over what it’s made to it can be catastrophic in many ways. Prior to having a Thermographic scan that piece of equipment is working much harder than it should be which is requiring an additional strain on your energy. In addition, the equipment it is running to/from is also working harder to keep up. The room it’s stored in is running hotter because of the heat given off by this equipment.

You are losing energy. This will continue until the equipment fails, at which time you will acquire a very expensive repair or replacement expense for that piece of equipment and perhaps other pieces that have been negatively affected by this defect. Not to mention you don’t know when this piece of equipment will fail, which puts you at risk for an arc, an outage or worse an explosion. By knowing your electrical system, you eliminate waste. Waste of energy, waste of equipment, waste of time, waste of money. By knowing your electrical system through infrared, you are doing your pocketbook and your Earth a favor.

ENERGY SUSTAINABLE!

Save Energy: Protect Our Planet

When Equipment Fails….

Waste Enters Our Earth.

Prevent generations of hazardous waste. Prolong your equipment’s life to save money and to save having to replace with new equipment. When your equipment’s life is cut short you will need to discard of the old equipment, although recycling old equipment is common, many parts of these units are not recyclable and in recycling you are still adding components into the air that are not good for our ozone. In addition, by having to purchase equipment years before you should have you are using more and more of our natural resources to replace these units.

Transformers are typically designed to last at least 30 years. A study conducted by a leading national loss prevention insurance company has estimated the average life span of transformers is 12 years. There are two reasons for this: overloading and poor maintenance.

With a PM program you can add 18+ years to a transformer. Now imagine all the transformers you have out there.

This cycle can prevent an estimated 2 transformers from having to leave your facility and enter the world of recycling over a 30-year cycle. These are big and expensive pieces of equipment: Air Handlers, A/C Units, Chillers and so on. Do the math at all stores, all the equipment being replaced. By using what you have and not replacing it early you are not only doing your pocketbook a favor but you’re also doing the Earth a favor.

ENERGY SUSTAINABLE!

The United States Government SAYS:

“The Use of Infrared Can Detect Abnormally Hot Electrical Connections or Components, Detect Heat Created By Excessive Friction in Mechanical Systems and Can Detect Heat Losses and Air Leakage in Building Envelope and Roof Scanning.”